Engineering

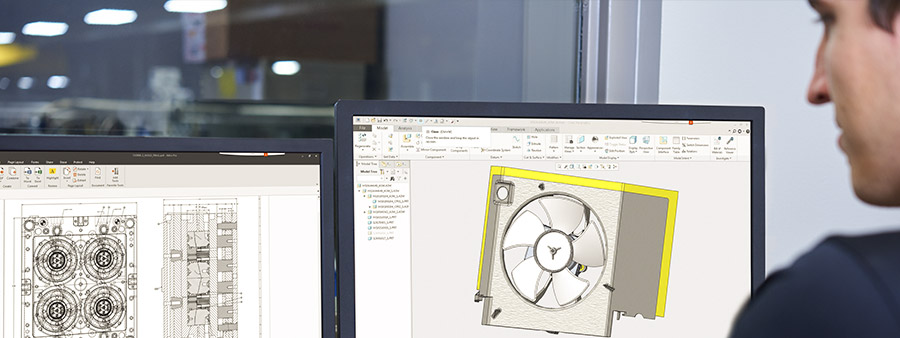

Our Engineers will be active in every step of your project. Beginning with your part design, we will utilize the Design for Manufacturability process (DFM) to evaluate your project and can make design improvement suggestions to improve your success. If your part warrants mold-flow or simulation, we can support your needs and offer design feedback to correct potential problems.

Material selection can be a daunting task. Our customers know their products’ end-use the best and, as a result, we will always stress to our customers the critical nature of independent evaluation and testing for their application. However, our experience in a wide range of industries allows us to help identify some potential material types and suppliers for evaluation.

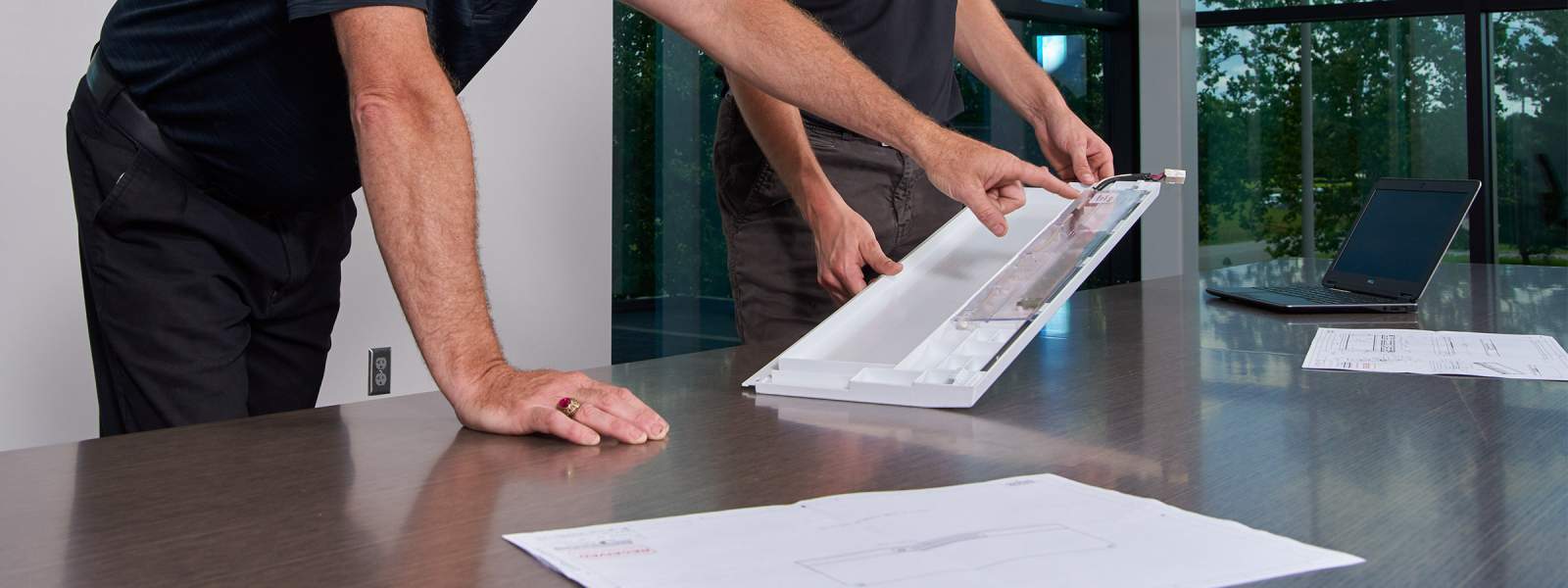

Complex parts are no problem for Wabash. We’ve been managing injection mold tool builds for over 45 years and have a great base of tooling vendors to work with. Our group of engineers has extensive experience managing tool builds for highly detailed complex part designs.

Once your part concept is nearing completion, our Automation & Assembly Engineers will manage any after molding operations that need to take place. From a simple screw installation to any of our growing offering of decoration and assembly operations, we will develop a process that is efficient from both a cost and complexity standpoint.

Our molding process is centered around scientific injection molding. This approach to process development allows us to determine optimum injection molding parameters for your product. A properly decoupled molding process allows for wider processing windows and more consistent parts for our customers. This means tighter control over your critical tolerances and a better overall quality product.