Our Process

Our team includes some of the most experienced and knowledgeable Engineers in the thermoplastic injection molding industry. Our talented staff has over 45 years of experience working with a full spectrum of injection molding processes. From our specialties in 2K / two-shot molding and gas assist, to our complete line of state-of-the-art molding equipment and assembly technologies, we have the capabilities you need. We can manage your project through all phases including the early conceptual stages, design validation and prototyping, tooling, and production. We’re committed to partnership with our customers throughout the entire design process to ensure we deliver a finished product, on time. We believe the best products result from good communication between the customer and the Wabash team.

Discover

The project management process starts with effective communication. Our engineers will take time to understand your needs and guide you on the path that provides the best opportunity to meet your goals. We understand the need to be competitive, responsive, on time, and to help develop a product that is effective as intended.

Your project will be assigned a dedicated engineer that supports the project from the initial concept stage, design for manufacturability (DFM), tooling, auxiliary & assembly equipment, process development, and on to production launch.

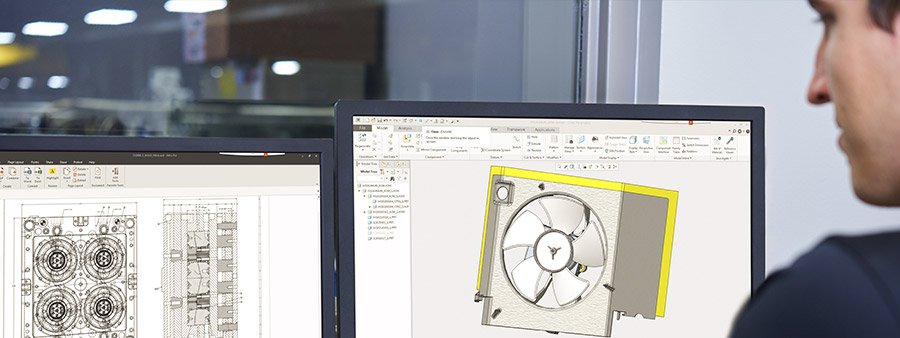

Wabash Plastics Engineers have many types of CAD software at their disposal. Our goal is to maintain flexibility to support all customers CAD systems - we will never require a customer to conform to our tools. We can support native CATIA, Pro Engineer / CREO, Solidworks, and AutoCAD files as many universal CAD file types including IGES, STL, and STEP. If it’s not listed, don’t worry. Give us a call and we will work to accommodate your needs.

DEVELOP

Our experience is wide ranging and our biggest strength is our expertise in tool design and automation dedicated to reducing your costs.

Designing tooling and assembly equipment utilizing value engineering allows you to keep your project within budget and realize long term savings.

Expertise in tool design and automation dedicated to reducing your costs.

We will select the appropriate tooling technologies to offer the greatest degree of part design freedom while maximizing tooling longevity. Tooling is a large investment and we will help you find the right balance between cost and longevity that meets your project needs.

Learn More about Wabash processes, capabilities, and equipment

DELIVER

At Wabash, we understand the impact that a delay can have on your business. Our entire team is dedicated to ensuring that delays are a thing of a past.

From concept to sunset, our entire team is focused on delivering the effective project management and communication required to make sure every stage of your project is managed and delivered on time.

Our world class tools, equipment, and systems support our goals of providing unparalleled levels of customer satisfaction in the industry.