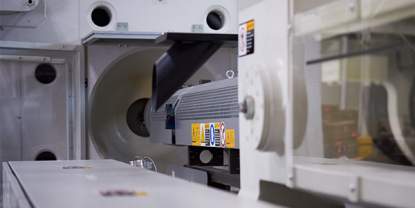

Stack Molding

Double the output using the same size injection molding machine

Wabash Plastics’ extensive experience with stack tools can save you money. This technology takes a standard tool and adds a second plane of cavities. Opening on two planes instead of one allows for twice the cavitation while using the same size injection molding machine. This translates to higher throughput and a direct savings to our customers.

Product Inspirations

- Blower & Housings

- Laundry Baffles

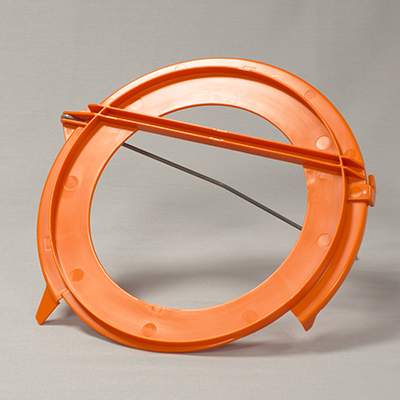

- HVAC Orifice Rings

- Laundry Tub Covers