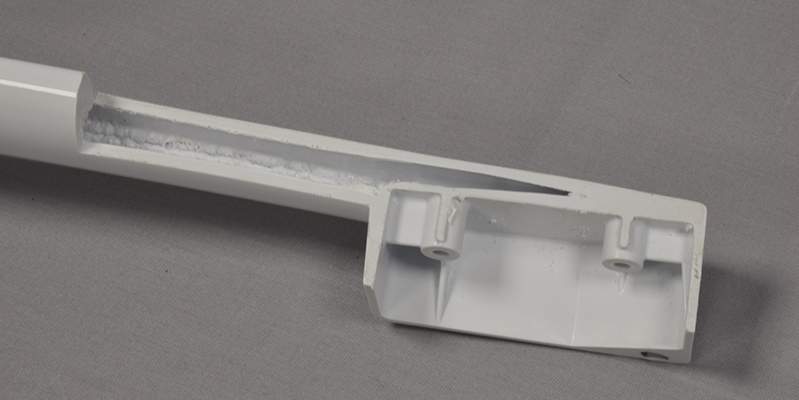

Gas Assist Injection Molding

Mold thick parts or sections while reducing cycle time and part weight.

With over 12 million gas assist appliance handles manufactured, gas assist is a technology that has been a part of our offering for over 30 years. This process uses high pressure nitrogen to displace molten plastic after injection into the tool. This can be used in a localized area to pack out a thick section and eliminate sink marks or completely displace the material leaving a hollow section behind.

Product Inspirations

- Refrigerator Handles

- Range Handles

- Equipment Handles